Home About Us EVENTS & NEWS The Future of Energy Storage: Battery Technology and Industry 4.0 Integration

The Future of Energy Storage: Battery Technology and Industry 4.0 Integration

The Future of Energy Storage: Battery Technology and Industry 4.0 Integration

Battery technology is at the vanguard of this shift as the globe turns more and more to sustainable energy sources.

Battery technology has emerged as a key enabler in the pursuit of cleaner and more efficient ene

rgy systems, from supplying dependable energy storage for renewable sources like solar and wind to powering electric vehicles (EVs).

In order to solve global energy issues like lowering carbon emissions and promoting energy independence, battery technology development is essential.

The Evolution of Battery Manufacturing

Significant advancements in battery technology have been made in the last few decades.

Modern and more effective alternatives, like lithium-ion (Li-ion) batteries, have replaced the conventional lead-acid batteries that once dominated the market.

The demand for greater energy density, quicker charging times, and longer lifespans—particularly in electric vehicles and large-scale energy storage applications—is what is driving these advancements.

Emerging technologies like solid-state batteries and next-generation chemistries, in addition to Li-ion batteries, have the potential to completely transform the market.

By offering substantial improvements over current technologies, these developments promise batteries with increased energy capacity, quicker charging, and improved safety features.

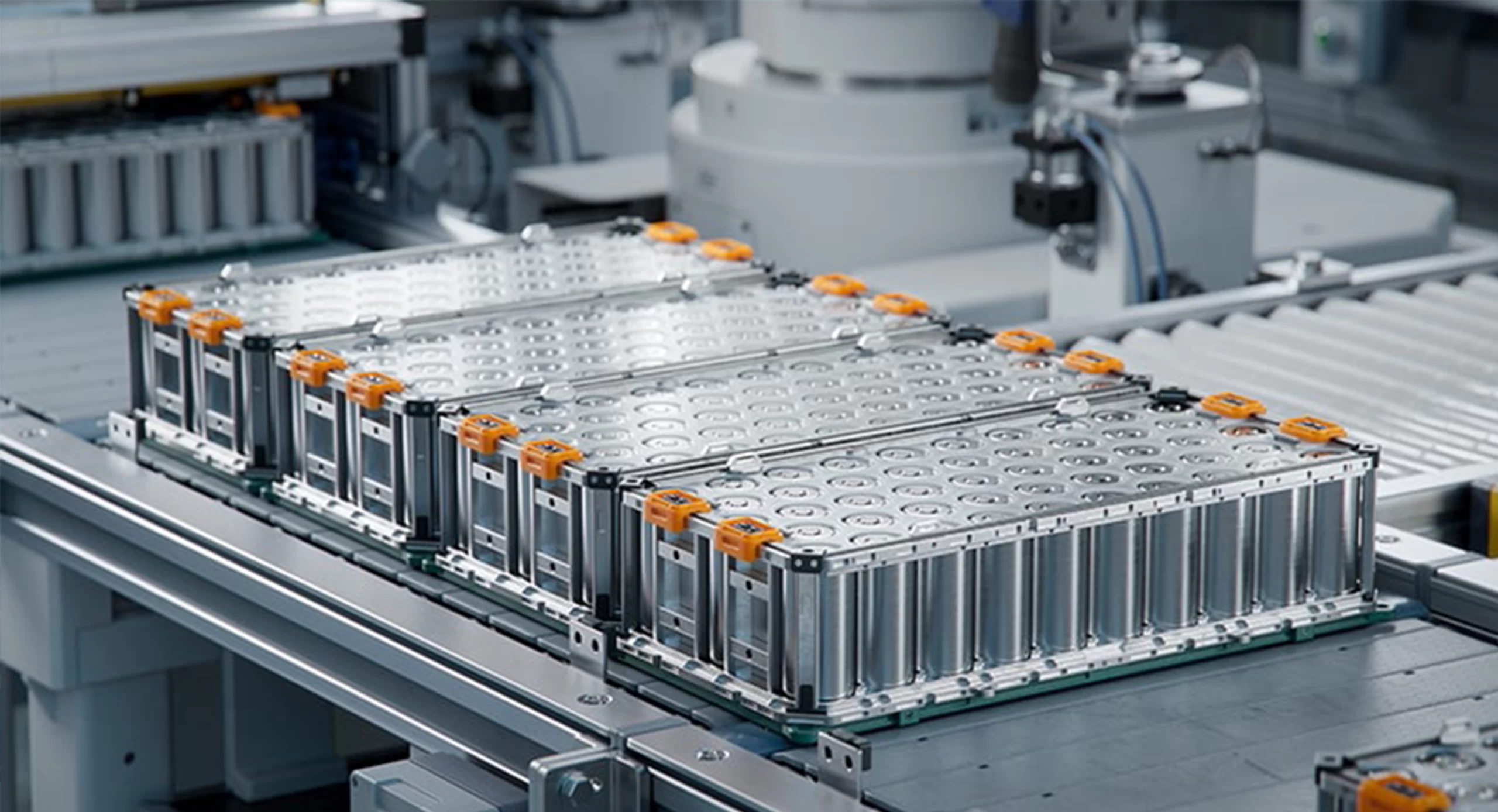

The Battery Manufacturing Process: Core Technologies and Key Components

Batteries, particularly those used in contemporary energy storage systems, are made in a complicated process that includes several crucial steps.

Every step is essential for both maximizing production costs and guaranteeing the battery’s efficiency.

In order to attain the intended performance, the chemical composition and structure of the electrode materials must be carefully regulated during the initial preparation stage.

The production of batteries typically involves a number of processes, such as cell assembly, formation, aging, and electrode preparation.

Each process has been significantly optimized by the combination of Industry 4.0 principles and battery technology.

Throughout the production line, automation, real-time monitoring, and data analysis have increased productivity, consistency, and quality.

Anodes, cathodes, separators, and electrolytes are the essential parts of contemporary batteries. Every component is essential to the storage and release of energy.

Graphite is typically used for the anode, which stores lithium ions during charging and releases them during discharge.

Lons can flow between the anode and cathode thanks to the electrolyte and the separator, which guards against short circuits.

Automation and Smart Manufacturing in Battery Production

The battery technology industry has entered a new era of smart manufacturing thanks to Industry 4.0.

Highly effective, scalable battery production is made possible by automation systems driven by artificial intelligence (AI) and data analytics.

Manufacturers can ensure quality control and predictive maintenance by monitoring every step of the production process with smart sensors and real-time data collection.

As a result of this technological integration, production lines have been optimized to minimize waste and human error, which has decreased costs and increased production efficiency.

Additionally, AI algorithms are being used to improve battery testing and defect detection, guaranteeing that customers receive only the best batteries.

Enhancing Energy Storage with Next-Generation Battery Technologies

Although lithium-ion batteries continue to be the most popular energy storage option, next-generation chemistries will probably shape battery technology in the future.

For instance, compared to conventional lithium-ion batteries, solid-state batteries promise to provide higher energy densities and quicker charging times.

This makes them a perfect fit for uses like large-scale renewable energy storage and electric vehicles that demand high energy capacity and rapid recharge times.

Furthermore, novel materials such as sodium-ion and lithium-sulfur are being investigated for their potential to provide even better performance at a reduced cost.

These technologies will be essential for improving the overall performance of energy storage systems and overcoming present constraints like raw material availability and cost.

18S-24S 200A BMS for Golf Cart &Energy Storage &3-Wheeled Vehicle &Motorcyle

The Role of Quality Control and Safety in Battery Manufacturing

Ensuring the safety and dependability of batteries is crucial as battery technology develops.

Strict quality control procedures that keep an eye on everything from the raw materials to the finished product are necessary for the production of high-quality batteries.

Important quality control procedures include verifying material purity, making sure electrodes are aligned correctly, and conducting comprehensive battery testing in a range of scenarios to validate performance indicators.

Another important consideration in battery manufacturing is safety.

Through sophisticated safety procedures, the risk of thermal runaway, overcharging, or short circuits must be carefully controlled.

Using Battery Management Systems (BMS) to control temperature, voltage, and charge/discharge cycles is one of these protocols that guarantees the battery runs within safe bounds.

Sustainable and Green Manufacturing Practices

The need to address the environmental impact of battery production is growing along with the demand for battery technology.

Green manufacturing techniques, like using eco-friendly components, recycling materials, and lowering energy consumption, are becoming crucial.

In order to cut waste and establish a circular economy for battery technology, the industry is also striving to enhance battery recycling techniques.

Stricter environmental regulations are being enforced by regulatory agencies around the world, which is forcing producers to create more environmentally friendly production techniques.

Battery technology will continue to become even more environmentally friendly as sustainable materials and processes are developed, helping to create a cleaner world.

The Impact of U.S. Tariffs on the Battery Manufacturing Industry

Political and economic issues are also posing problems for the global battery technology sector.

The United States government’s decision to impose tariffs on imported batteries and components is one example of such a challenge.

Due to increased production costs and decreased profit margins, these tariffs have affected manufacturers, especially those in nations with close export ties to the United States.

These tariffs put battery manufacturers in a difficult position where they have to strike a balance between maintaining high standards of quality and being cost competitive.

As a result, businesses might have to pass those costs on to customers or absorb the extra expenses, which could have an impact on product pricing.

Additionally, the tariffs have increased supply chain costs for manufacturers who depend on imported materials like cobalt and lithium.

Many manufacturers are looking into new ways to lessen the impact of these tariffs in spite of these obstacles.

This entails investing in local supply chains, moving production to areas with less trade restrictions, and streamlining production procedures to reduce cost increases.

As businesses adjust to these new realities, the battery technology industry will continue to be shaped by the changing nature of global trade.

The Future: Battery Technology and Industry 4.0

Battery technology has an extremely bright future.

We can anticipate even more advancements in battery manufacturing as Industry 4.0 continues to revolutionize manufacturing.

AI, data analysis, and automation will further optimize production procedures, increasing battery manufacturing’s speed, accuracy, and efficiency.

Furthermore, new applications will be made possible by the advancement of battery chemistries and enhanced energy storage systems, which will accelerate the switch to renewable energy sources and electric vehicles.

Electric vehicles and grid energy storage are just two of the industries that will be significantly impacted by the continuous developments in battery technology.

Cleaner, more economical, and more efficient energy solutions will become available as these technologies develop further, helping to create a more sustainable future.

Our goal at Shenzhen Ayaa Technology Co., Ltd. is to develop battery technology and offer innovative solutions to a range of industries.

We stay at the forefront of battery technology innovation because of our commitment to research and development.

Contact Us

SHARE

News Recommend

-

How does AYAATECH BMS work in E-scooters

01/16/2025 -

2024 battery show in Detroit,USA.

10/08/2024