Home About Us EVENTS & NEWS Best Forklift Battery Solutions: 5 Ayaatech BMS Options Compared

Best Forklift Battery Solutions: 5 Ayaatech BMS Options Compared

Best Forklift Battery Solutions: 5 Ayaatech BMS Options Compared

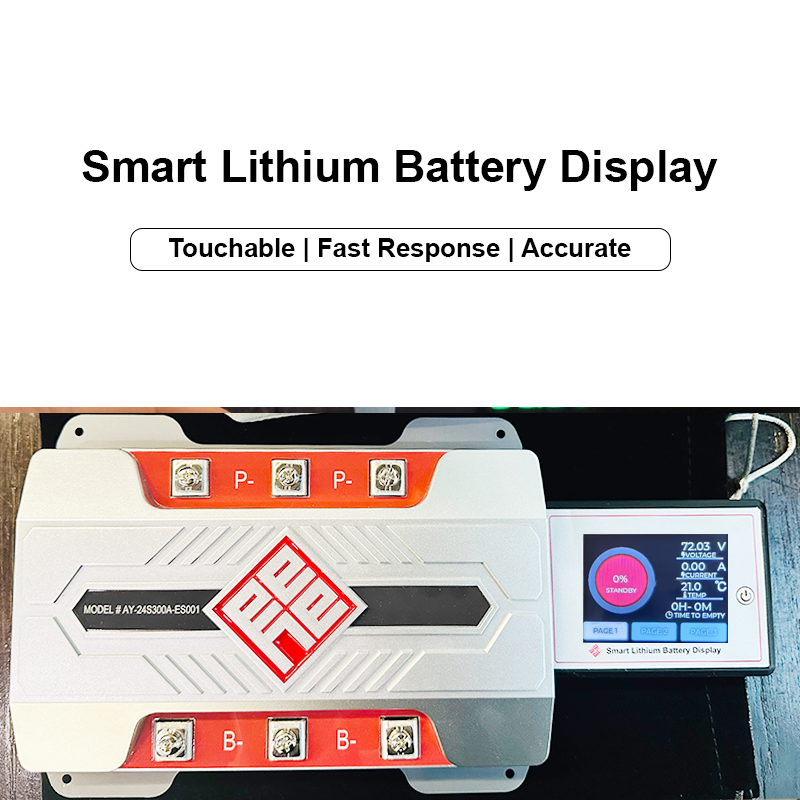

1. What Makes the 7S-24S 300A BMS the Ultimate Multi-Purpose Solution?

Model: AY-L24S300A-ES001

Ideal for: Large warehouses, multi-shift operations, and extreme temperature environments This industrial-grade BMS stands out with its unmatched versatility and power handling. The 300A continuous current rating (1000A peak) ensures reliable performance even during intensive 24/7 warehouse operations. Unlike standard forklift BMS units, this model’s 7S-24S voltage range (24V-72V) makes it compatible with nearly all lithium battery chemistries used in modern forklifts, including LiFePO4 and LTO.

Key advantages for forklift applications:

-

- All-Weather Operation: Built-in battery heating maintains optimal performance in cold storage facilities (as low as -20°C), while the aluminum alloy heat sink prevents overheating in hot industrial environments.

-

- Fleet Management Ready: Optional 4G/WiFi modules enable real-time monitoring of entire forklift fleets, tracking battery health across multiple shifts.

-

- Industrial-Grade Protection: Triple-layer safety mechanisms prevent catastrophic failures from overcurrent (up to 1000A peak detection), short circuits, and thermal runaway.

-

- Future-Proof Design: The same BMS can be repurposed for solar storage or other equipment, reducing long-term costs for diversified operations.

Best for: Large distribution centers needing reliable performance across varied temperatures and shift patterns.

2. Why Choose the 16S-20S 110A BMS for Medium-Duty Forklifts?

Model: AY-LS30S110A-H165

Ideal for: Retail warehouses, light manufacturing, and rental fleets Balancing performance and affordability, this 110A BMS delivers optimized power management for typical 48V-72V forklift batteries. The 16S-20S configuration precisely matches common LiFePO4 setups, while advanced balancing algorithms extend battery life by up to 30% compared to basic BMS units. Its compact design integrates seamlessly with most standard forklift battery compartments.

Standout forklift-specific features:

-

- Smart Charge Optimization: Automatically adjusts charging parameters based on usage patterns, ideal for rental fleets with varying operators.

-

- Vibration-Resistant Construction: Reinforced components withstand the constant shocks typical in warehouse environments.

-

- Maintenance Alerts: RS485/CAN interfaces connect to warehouse management systems, sending proactive maintenance notifications before issues arise.

-

- Plug-and-Play Installation: Pre-configured for common forklift battery voltages (51.2V-84V) with color-coded connectors for error-free setup.

Best for: Operations needing reliable performance without complex installation or monitoring requirements.

3. How Does the 18S-24S 200A BMS Power Heavy Industrial Forklifts?

Model: AY-LS24S200A-H245

Ideal for: Steel mills, lumber yards, and container handling Engineered for extreme conditions, this high-voltage BMS handles the most demanding forklift applications. The 200A continuous current (500A peak) powers heavy loads up steep ramps, while the 18S-24S range supports high-capacity 72V+ battery systems common in industrial forklifts. Unique to this model is its dual-stage overcurrent protection, which provides warning alerts before complete shutdown – critical for preventing mid-operation stoppages.

Industrial-grade advantages:

-

- Heavy-Duty Cooling: Oversized heat sinks with industrial fans maintain stable temperatures during continuous heavy lifting.

-

- Shock Protection: Military-grade components withstand vibrations from rough terrain and heavy loads.

-

- Load-Adaptive Balancing: Automatically adjusts cell balancing intensity based on current draw, perfect for variable load operations.

-

- Dust/Water Resistance: IP65 rating protects against airborne particles and splashes in harsh environments.

Best for: Heavy industry applications where equipment must handle extreme loads and harsh conditions.

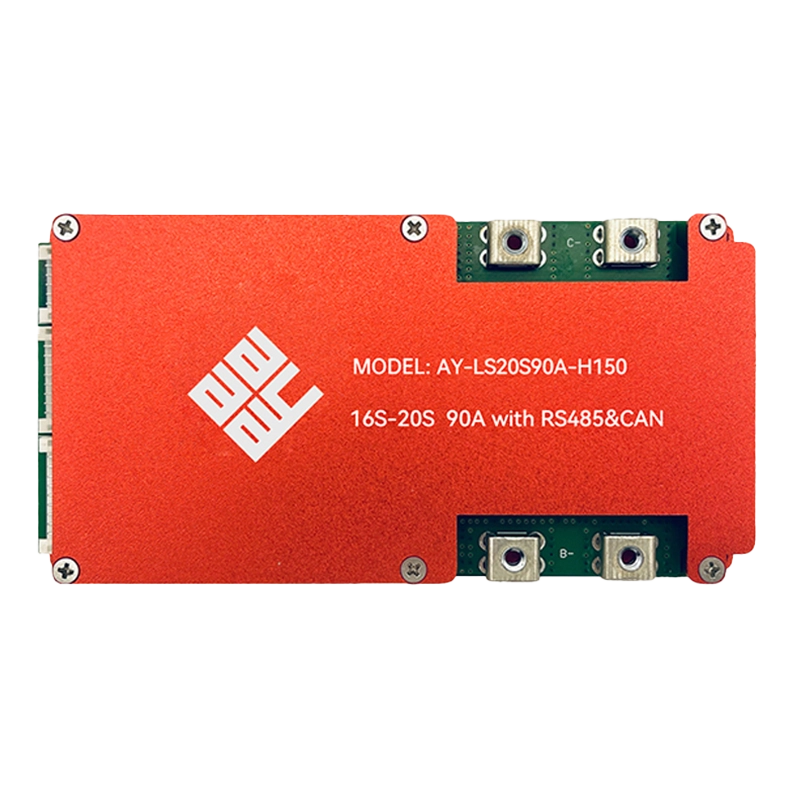

4. Can the 16S-20S 90A BMS Simplify Your Electric Forklift Conversion?

Model: AY-LS20S90A-H150

Ideal for: Small businesses, electric conversions, and backup fleets This compact BMS provides essential protection for smaller forklifts and conversion projects at an accessible price point. Despite its modest 90A rating, it includes all critical safety features in a space-saving 150mm × 76mm package. The unit’s auto-learning algorithm gradually optimizes performance based on your specific usage patterns, making it particularly suitable for businesses transitioning from lead-acid to lithium batteries.

Conversion-friendly features:

-

- Legacy System Compatibility: Works with most existing forklift charging infrastructure, minimizing conversion costs.

-

- Simple Monitoring: Basic RS485 interface connects to affordable displays for small operations.

-

- Adaptive Charging: Automatically detects and adjusts to different charger types common in mixed fleets.

-

- Maintenance-Free Operation: Sealed design requires no periodic adjustments, ideal for operations without dedicated maintenance staff.

Best for: Small warehouses and businesses converting from lead-acid to lithium power.

5. Does Your Operation Need 400A Power? The Industrial-Grade Solution

Model: AY-L24S300A-ES001

Ideal for: Mining, port operations, and heavy manufacturing Representing the pinnacle of forklift BMS technology, this 400A-capable system powers the most demanding material handling equipment. While nominally rated for 300A continuous current, its robust design handles 400A surges common in heavy container handling. The 7S-24S voltage flexibility accommodates specialized high-power forklifts, while optional regenerative braking support captures energy during descent – particularly valuable in dockyard applications with frequent elevation changes.

Extreme-duty features:

-

- Military-Grade Components: Designed for 100,000+ charge cycles in harsh conditions.

-

- Remote Diagnostics: Optional GPS/4G enables manufacturer-level troubleshooting worldwide.

-

- Parallel Battery Support: Manages multiple battery packs simultaneously for extended runtime.

-

- Customizable Protection: Adjustable parameters accommodate specialized forklift configurations.

Best for: Extreme-duty applications where maximum power and reliability are non-negotiable.

FAQ

Q1: Why is a BMS critical for forklift batteries, and what key functions does it provide?

A1:

-

Safety: Prevents thermal runaway (critical for lithium-ion), overcharging, and deep discharge.

-

Performance: Optimizes charge/discharge cycles to extend battery lifespan (e.g., lead-acid sulfation prevention).

-

Data Insights: Tracks State of Health (SOH), State of Charge (SOC), and cycle counts for predictive maintenance.

-

Compliance: Meets OSHA and ISO standards for workplace battery safety.

Q2: How does a BMS differ for lead-acid vs. lithium-ion forklift batteries?

A2:

-

Lead-Acid BMS: Focuses on equalization charging to prevent stratification and sulfation. Typically uses passive balancing.

-

Lithium-Ion BMS: Requires active balancing, strict voltage/temperature monitoring per cell, and CAN bus communication for fleet management.

-

Cost: Lithium BMS is more complex but reduces long-term maintenance costs.

Q3: What are the top signs of a failing forklift BMS?

A3:

-

Unexpected Shutdowns: Battery cuts off prematurely despite showing charge.

-

Inaccurate SOC Readings: Fully charged battery depletes too fast.

-

Overheating: BMS fails to regulate temperature during charging/operation.

-

Error Codes: Alerts like “Cell Imbalance” or “Communication Fault” (common in lithium systems).

Q4: How can a BMS improve energy efficiency in electric forklifts?

A4:

-

Peak Load Management: Limits current spikes during heavy lifting to protect cells.

-

Regenerative Braking: Captures energy during deceleration (requires advanced BMS coordination).

-

Adaptive Charging: Adjusts charge rates based on battery temperature and usage history.

-

Fleet Syncing: Integrates with warehouse management systems (e.g., Toyota I_Site) to schedule charging during off-peak hours.

Q5: What advancements are shaping the future of forklift BMS?

A5:

-

AI-Driven Predictive Maintenance: Uses historical data to forecast failures (e.g., sudden voltage drops).

-

Wireless Cloud Monitoring: Real-time BMS data accessible via IoT platforms (e.g., EnerSys’s iON system).

-

Fast-Charging Compatibility: Enables opportunity charging (15–30 min top-ups) without degrading lithium batteries.

-

Second-Life Applications: Repurposes retired forklift batteries for stationary storage (e.g., BYD’s Energy Storage solutions).

Conclusion

Selecting the best forklift battery management system depends on your specific voltage requirements, current demands, and operational environment. Ayaatech’s range offers solutions from compact 90A units for small operations to industrial 400A-capable systems for heavy industry. Consider your typical load weights, shift duration, and environmental conditions when choosing – our technical team can help match the perfect BMS to your forklift fleet’s needs.

SHARE

News Recommend

-

How does AYAATECH BMS work in E-scooters

01/16/2025 -

2024 battery show in Detroit,USA.

10/08/2024