Home About Us EVENTS & NEWS Battery Management System Lithium Ion Trends in 2025: AI Integration and Global Market Demands

Battery Management System Lithium Ion Trends in 2025: AI Integration and Global Market Demands

Battery Management System Lithium Ion Trends in 2025: AI Integration and Global Market Demands

In 2025, the global energy storage and electric mobility industries are undergoing a rapid transformation.

At the heart of this evolution is the battery management system lithium ion, a technology that has become indispensable in optimizing performance, ensuring safety, and prolonging the lifespan of lithium-based batteries.

As new market demands rise and artificial intelligence begins to play a more critical role, the future of the battery management system lithium ion industry is brighter and more innovative than ever.

What Is a Battery Management System for Lithium Ion?

A battery management system lithium ion (BMS) is an electronic interface that manages and protects lithium-ion battery packs.

It ensures safe operation, monitors vital statistics such as voltage, current, and temperature, and implements protections against overcharging, over-discharging, and short circuits.

The role of a BMS becomes even more crucial when battery packs are used in high-demand applications like electric vehicles (EVs), renewable energy storage systems, and advanced robotics.

Why Do Lithium-Ion Batteries Need a Battery Management System?

Lithium-ion batteries require a Battery Management System (BMS) because they are highly sensitive to operating conditions, and without proper management, they can pose serious safety, performance, and longevity risks.

Here’s why a BMS is essential:

1. Precise Voltage Control

Each lithium-ion cell operates safely only within a specific voltage range (typically between 2.5V and 4.2V).

Overcharging a cell can cause electrolyte breakdown, overheating, and even fire or explosion.

Over-discharging can lead to irreversible capacity loss or cell failure.

A BMS continuously monitors individual cell voltages to ensure they stay within safe limits, preventing damage.

2. Temperature Monitoring and Control

Lithium-ion batteries are sensitive to temperature extremes.

High temperatures accelerate degradation and increase the risk of thermal runaway.

Low temperatures reduce performance and may damage the cells.

A BMS includes temperature sensors and can trigger protection mechanisms (like cooling systems or shutdowns) if the battery becomes too hot or too cold.

3. Cell Balancing

In a battery pack, variations between cells are inevitable.

Over time, cells can become imbalanced, with some charging or discharging faster than others.

This reduces overall efficiency and lifespan.

BMS systems use active or passive balancing techniques to equalize cell voltage and capacity, ensuring consistent performance.

4. State of Charge (SOC) and State of Health (SOH) Estimation

Knowing how much energy is left (SOC) and the battery’s condition over time (SOH) is vital for system reliability and user experience.

A BMS calculates SOC and SOH using advanced algorithms, helping users make informed decisions and maximizing battery life.

5. Protection from Fault Conditions

The BMS acts as a safeguard against:

Overcurrent Short circuits Reverse polarity Internal faults.

It shuts down or isolates the battery in case of dangerous anomalies to prevent damage or hazards.

A Battery Management System is critical to the safe, efficient, and long-lasting operation of lithium-ion batteries.

Without it, the battery is vulnerable to degradation, malfunction, and even catastrophic failure.

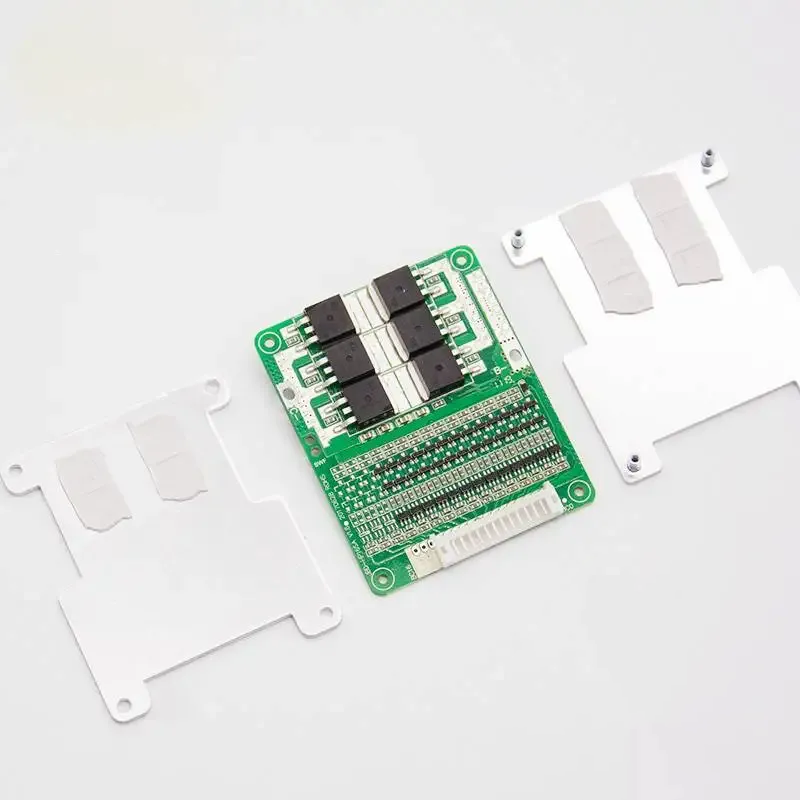

Core Components of a Lithium-Ion Battery Management System

A Battery Management System (BMS) for lithium-ion batteries is a sophisticated combination of hardware and software designed to ensure safe, efficient, and long-lasting battery performance.

The effectiveness of a BMS depends largely on its core components, each playing a specific role in managing the battery pack.

1. Battery Monitoring Unit (BMU)

This is the brain of the system.

It collects real-time data from all sensors and modules in the battery pack.

Monitors voltage, current, and temperature.

Executes safety algorithms and communicates with other control units.

Calculates State of Charge (SOC) and State of Health (SOH).

2. Voltage Sensors

These sensors monitor the voltage of each individual cell in the battery pack.

Ensures no cell exceeds safe charging/discharging limits.

Enables cell balancing by detecting voltage differences between cells.

3. Temperature Sensors

Placed at strategic locations within the battery pack, these sensors:

Monitor internal temperatures to detect overheating.

Help the BMS trigger cooling systems or emergency shutdown protocols.

Enable thermal management strategies for optimized performance.

4. Current Sensor (Shunt or Hall Effect Sensor)

Measures the charge and discharge current flowing in and out of the battery.

Vital for calculating SOC, energy usage, and power output.

Protects against overcurrent and short-circuit conditions.

5. Cell Balancing Circuit

This component equalizes the charge across all cells, preventing weaker cells from being overstressed.

Passive balancing dissipates excess energy as heat.

Active balancing redistributes energy between cells.

Improves battery lifespan and consistency.

6. Protection Circuitry

Provides over-voltage, under-voltage, over-current, and over-temperature protection.

Automatically disconnects the battery from the load or charger if thresholds are exceeded.

Critical for preventing thermal runaway and battery damage.

7. Communication Interface (e.g., CAN, SMBus, UART, RS485, Bluetooth)

Enables data exchange between the BMS and external systems:

EV controllers, chargers, display units, cloud monitoring platforms.

Allows remote diagnostics, firmware updates, and performance optimization.

8. Microcontroller or Processor

The central processor runs the BMS software and executes key control algorithms.

Processes sensor data in real-time.

Implements SOC/SOH estimation, balancing logic, and fault detection.

The core components of a lithium-ion battery management system work together to protect the battery, optimize its usage, and extend its lifespan.

Each part—whether it’s a simple sensor or a complex control algorithm—is essential to the performance, safety, and intelligence of the BMS.

AI Integration in Battery Management System Lithium Ion

One of the most revolutionary trends in 2025 is the integration of artificial intelligence into the battery management system lithium ion.

AI-enhanced BMS solutions utilize machine learning algorithms to predict battery health (State of Health or SOH) and State of Charge (SOC) with greater precision.

This predictive capacity reduces the risk of unexpected battery failures, improves charging efficiency, and allows real-time optimization of energy usage.

Global Market Demands and Regulatory Pressure

The international push toward electrification and decarbonization is expanding the global market for battery management system lithium ion.

Countries across North America, Europe, and Asia are ramping up EV subsidies, enforcing carbon-neutral regulations, and investing in renewable energy infrastructure.

These trends are driving the demand for advanced BMS technologies that not only manage battery packs effectively but also contribute to broader grid stability.

In this context, BMS manufacturers must meet higher standards for reliability, cybersecurity, and environmental compliance.

Hardware and Software Innovations in 2025

Technological advancement in both hardware and software is another key driver of battery management system lithium ion development in 2025.

High-resolution sensors, improved microcontrollers, and advanced communication protocols such as CAN, SMBus, and Bluetooth are becoming standard.

Meanwhile, BMS software now features more intuitive interfaces, real-time diagnostics, and cloud-based analytics platforms.

Key Applications in Energy Storage and EVs

The battery management system lithium ion is not limited to electric vehicles.

It plays a pivotal role in residential energy storage systems, commercial microgrids, and large-scale utility projects.

In 2025, demand for off-grid and hybrid solar storage systems is soaring, especially in emerging markets.

Efficient BMS units enable better peak load shifting, grid backup, and energy arbitrage.

The Push for Safety, Efficiency, and Lifecycle Management

Modern battery management system lithium ion designs prioritize safety more than ever before.

Thermal management, fault isolation, and automated shut-down sequences are essential features.

Additionally, life cycle monitoring and degradation modeling help ensure that the battery remains within optimal operating conditions.

Competitive Landscape and Strategic Differentiators

As more players enter the battery management system lithium ion market, competitive differentiation comes down to performance, adaptability, and support services.

Shenzhen Ayaa Technology Co., Ltd. stands out by offering custom BMS designs tailored to customer-specific requirements in EVs, medical devices, drones, and industrial machinery.

Their team’s 20+ years of experience in engineering and global market operations ensures that clients receive not just products but complete energy management solutions.

Sustainability and End-of-Life Management

Sustainability is an emerging priority in 2025.

The BMS lithium ion must now consider end-of-life recycling, energy recovery, and material reuse.

BMS units are being designed to track and log lifecycle data that helps recyclers identify viable cells and materials.

Challenges Facing the Industry

Despite the growth, the BMS lithium ion industry faces several challenges in 2025.

These include:

Tariffs and trade tensions, particularly between the U.S. and China, which have led to fluctuating component costs.

Shortages in semiconductor supplies impacting BMS production timelines.

Increased cybersecurity threats targeting connected battery systems.

What’s Next for Battery Management System Lithium Ion?

The future of battery management system lithium ion will be shaped by AI, IoT, and smart grid integration.

Autonomous energy systems that self-optimize based on grid demand and weather forecasts will rely heavily on intelligent BMS solutions.

As electric aviation, autonomous vehicles, and green shipping evolve, BMS technologies will continue to adapt to more demanding environments.

Advantages of cooperation with Shenzhen Ayaa Technology Co., Ltd.

As 2025 ushers in a new era for lithium-ion battery systems, having a reliable BMS partner is more crucial than ever.

Ayaa Technology has a diversified supply chain, investment in secure firmware development and strategic partnerships in Europe and North America.

Shenzhen Ayaa Technology has introduced advanced safety protocols in their BMS products, including triple-layer temperature monitoring and active balancing circuits for long-term stability.

Shenzhen Ayaa Technology Co., Ltd. stands out by offering custom BMS designs tailored to customer-specific requirements in EVs, medical devices, drones, and industrial machinery.

Their team’s 20+ years of experience in engineering and global market operations ensures that clients receive not just products but complete energy management solutions.

Shenzhen Ayaa Technology Co., Ltd. offers world-class BMS lithium ion products backed by robust R&D, global service networks, and tailored engineering expertise.

Whether you’re building EV fleets, launching energy storage solutions, or designing next-gen wearable tech, Ayaa Technology delivers the intelligence behind the battery.

To learn more, visit www.ayaatech.com.

Contact Us

SHARE

News Recommend

-

How does AYAATECH BMS work in E-scooters

01/16/2025 -

2024 battery show in Detroit,USA.

10/08/2024