Home About Us EVENTS & NEWS Forklift Battery Suppliers: Understanding Their Manufacturing Process and Quality Control

Forklift Battery Suppliers: Understanding Their Manufacturing Process and Quality Control

Forklift Battery Suppliers: Understanding Their Manufacturing Process and Quality Control

In the world of industrial operations, forklift battery suppliers play a crucial role in ensuring the reliable performance of electric forklifts.

Whether you manage a warehouse, distribution center or manufacturing plant.

Choosing the right forklift battery supplier can maximize operational efficiency, reduce downtime and improve cost-effectiveness.

we will delve into the manufacturing process of forklift batteries, the quality control measures involved.

And how forklift battery suppliers maintain high standards to deliver top-notch products.

What Are Forklift Battery Suppliers?

Forklift battery suppliers are companies that specialize in providing batteries specifically designed for forklift trucks.

These batteries are the lifeblood of electric forklifts, supplying the necessary power to run these machines efficiently.

The primary types of batteries supplied by forklift battery suppliers include lead-acid batteries and lithium-ion batteries.

The choice of battery depends on the specific needs of the operation, including the runtime, charging speed, and total cost of ownership.

In recent years, lithium-ion batteries have become increasingly popular due to their higher energy density, longer lifespan, and faster charging capabilities.

This shift is changing the landscape of forklift battery suppliers, as they adapt to new technologies and the increasing demand for more efficient and sustainable solutions.

The Manufacturing Process of Forklift Batteries

The manufacturing process of forklift batteries is a highly specialized procedure that involves several intricate steps.

Each of these steps must meet strict standards to ensure the batteries’ performance, safety, and longevity.

Here’s an overview of the typical production process followed by forklift battery suppliers:

1. Battery Cell Production

The first step in the manufacturing process is the production of individual battery cells.

These cells are the core of any forklift battery and are responsible for storing and releasing electrical energy.

The process begins with the preparation of electrodes, which are made from a combination of materials like lead, lithium, and other metals depending on the battery type.

Lead-Acid Batteries: In the case of lead-acid batteries, the electrodes are coated with lead oxide, which is then immersed in an electrolyte solution of sulfuric acid.

Lithium-Ion Batteries: For lithium-ion batteries, the electrodes are typically made from lithium cobalt oxide or lithium iron phosphate.

And they undergo a sophisticated process of charging and discharging during production to ensure optimal performance.

2. Battery Assembly

Once the cells are produced, they are carefully assembled into battery packs.

This step involves connecting multiple cells in series or parallel to achieve the desired voltage and capacity.

The assembly process also includes integrating components like the battery management system (BMS).

Which monitors the state of the battery, preventing overcharging, over-discharging, and overheating.

The assembly process must be done with precision, as any deviation in the alignment or connections could lead to inefficiencies or even safety hazards.

3. Sealing and Packaging

After assembly, the batteries are sealed and packaged to ensure they are protected during shipping and installation.

This involves placing the battery in a durable casing and adding insulation and cooling systems where necessary.

These additional measures help safeguard the internal components and prevent damage during transportation.

Quality Control in Forklift Battery Manufacturing

Quality control is a critical aspect of the manufacturing process for forklift battery suppliers.

High-quality batteries maintain the performance and safety of electric forklifts, which are indispensable in a wide range of industries, including warehousing, logistics and manufacturing.

Let’s take a closer look at the quality control measures employed by leading forklift battery suppliers:

1. Testing and Inspection of Battery Cells

Before the cells are assembled into packs, they undergo rigorous testing to ensure they meet the required specifications. This includes testing for:

Voltage and Capacity: Ensuring each cell delivers the expected voltage and capacity under load conditions.

Internal Resistance: A critical factor in determining battery efficiency, internal resistance is measured to identify any issues that may lead to heat buildup or energy loss.

Cycle Life: The number of charge and discharge cycles the battery can undergo before losing capacity.

2. Performance Testing

Once the battery pack is assembled, it undergoes further testing to verify that it meets the performance standards for its intended use. Common tests include:

Charge and Discharge Tests: These tests simulate real-world usage by charging and discharging the battery multiple times to ensure it holds and delivers power efficiently.

Temperature Testing: Forklift batteries are subjected to high-temperature tests to ensure they can handle the heat generated during heavy-duty operations.

Vibration and Shock Tests: Since forklifts operate in rugged environments, the batteries are tested for durability under vibration and shock conditions.

3. Safety and Compliance

Safety is paramount when manufacturing forklift batteries.

Forklift battery suppliers must ensure that their products meet safety standards set by regulatory bodies such as UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission). Key safety checks include:

Short-Circuit Protection: Batteries are tested to prevent dangerous short circuits.

Overcharge and Over-discharge Protection: Systems are in place to ensure batteries are not overcharged or over-discharged, both of which can damage the battery or cause safety hazards.

Thermal Runaway Prevention: Safety measures are implemented to prevent thermal runaway, a phenomenon where the battery overheats uncontrollably.

4. Post-Production Quality Audits

After the batteries are manufactured, they undergo final quality audits before they are released for distribution.

These audits ensure that all components meet the required standards and that any potential issues are identified and rectified before the products reach customers.

Why Choose Shenzhen Ayaa Technology as Your Forklift Battery Supplier?

At Shenzhen Ayaa Technology, we take pride in being a leading forklift battery supplier with over 20 years of experience in the industry.

Our cutting-edge manufacturing processes, rigorous quality control systems, and commitment to innovation ensure that we deliver reliable, high-performance forklift batteries to our clients worldwide.

We offer a range of forklift batteries, including both lead-acid and lithium-ion options, each designed to meet the specific needs of various industries.

Our battery management systems (BMS) are designed to provide optimal battery performance, extending battery life, and improving overall efficiency.

By choosing Shenzhen Ayaa Technology as your forklift battery supplier, you are not just investing in a product, but in a long-term partnership that prioritizes quality, efficiency, and customer satisfaction.

FAQ

Q1:Why Does the Forklift Battery Industry Care About Supplier Reputation?

A1:The standing of a supplier may have an effect on how your firm operates:

Dependability: A reputable provider is more likely to offer premium goods that adhere to safety regulations.

Customer feedback: Testimonials and reviews might provide information about the dependability and caliber of the supplier’s services.

Q2:What Price Information Is Important to Consider When Selecting a Forklift Battery Supplier?

A2:Although price is an important concern, it shouldn’t be the sole one:

Long-Term Value vs. Initial prices: Although less expensive batteries could save money up front, they may need more upkeep or have shorter lifespans, which will raise prices over time.

Discounts for Large Purchases: A number of vendors provide discounts for large purchases, which can result in substantial cost savings.

Q3:How Can a Forklift Battery Supplier’s Customer Service Be Evaluated?

A3:Assessing customer service is crucial for enduring collaborations:

Response Times: Evaluate how fast they answer questions.

Support Availability: Find out if they provide restricted hours or round-the-clock assistance.

Technical Support: Verify that they have competent employees on hand to help with technical problems.

Q4:Why is post-purchase assistance so important to suppliers of forklift batteries?

A4:Your operating efficiency can be greatly impacted by after-sales support:

Maintenance Services: By providing maintenance services, suppliers can decrease downtime and increase battery life.

Options for warranties: A strong warranty offers peace of mind and shows that the company believes in its products.

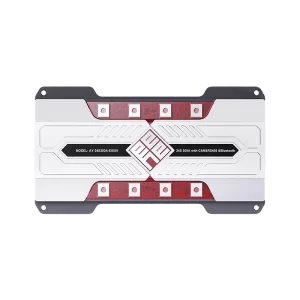

Model: AY-L24S300A-ES001(40-55$)

When selecting a forklift battery supplier, it is crucial to consider the supplier’s manufacturing processes, quality control measures, and technological capabilities.

With a focus on precision, innovation, and safety, leading forklift battery suppliers like Shenzhen Ayaa Technology ensure that your operations run smoothly, safely, and efficiently.

Whether you are upgrading your fleet or looking for a reliable long-term partner, choosing the right forklift battery supplier can significantly impact the performance and cost-effectiveness of your electric forklifts.

Trust in expertise, choose wisely, and enjoy the benefits of superior battery technology.

Contact Us

News Recommend

-

How does AYAATECH BMS work in E-scooters

01/16/2025 -

2024 battery show in Detroit,USA.

10/08/2024