Home About Us EVENTS & NEWS The Future of Battery Management System Technology and the Effects of U.S. Tariffs

The Future of Battery Management System Technology and the Effects of U.S. Tariffs

The Future of Battery Management System Technology and the Effects of U.S. Tariffs

In an era defined by electric vehicles, renewable energy storage, and high-performance portable electronics, the battery management system (BMS) has emerged as an indispensable technology.

As batteries become more energy-dense and mission-critical, managing their safety, longevity, and efficiency is paramount.

This article dives deep into the battery management system—its components, how it functions, and why it is essential for modern energy applications.

It also introduces Shenzhen Ayaa Technology Co., Ltd., a global leader in innovative BMS solutions, and how their expertise is shaping the future of power systems.

What Is a Battery Management System?

An electronic control unit that is integrated into a rechargeable battery system and keeps track of and regulates its operation is called a battery management system.

A BMS’s main objectives are to:

Ensure battery safety

Optimize energy usage

Extend battery life

Provide real-time diagnostics and data

Battery packs are susceptible to overcharging, overdischarging, overheating, and cell imbalance in the absence of an appropriate battery management system. Reduced performance or potentially hazardous failures can result from these issues.

Why the Battery Management System Is Critical

The battery management system is essential, not simply a convenience, and it is crucial in high-value industries like:

Electric vehicles (EVs): where the vehicle’s performance and costs depend heavily on battery longevity and energy efficiency.

Energy storage systems (ESS): where the stability of the grid depends on long-term functioning and reliability

Medical devices and drones: where battery failure could have life-threatening repercussions and safety is a must.

Consumer electronics: where users demand maximum runtime and minimal risk.

All of these needs are satisfied by a top-notch battery management system, which also preserves system-level intelligence.

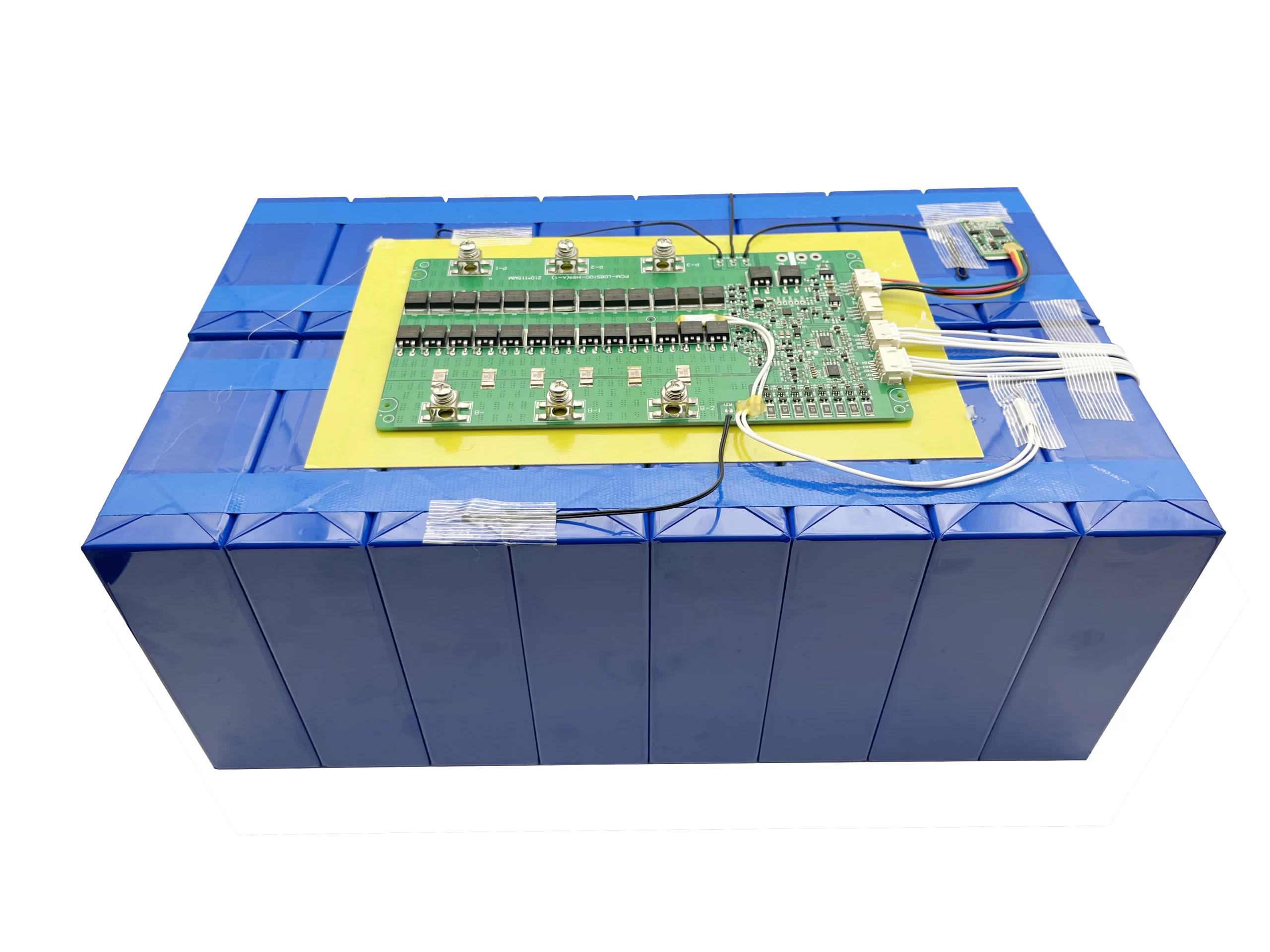

Core Components of a Battery Management System

A modern battery management system involves multiple interconnected units working in harmony:

1. Battery Monitoring Unit (BMU)

This device continuously measures the temperature, voltage, and current in each cell.

Precise information from the BMU aids in evaluating the State of Health (SOH) and the State of Charge (SOC).

2. Microcontroller Unit (MCU)

The MCU processes sensor data and conducts algorithms for battery estimates, balance, protection, and communication.

The battery management system’s “brain” is this.

3. Balancing Circuit

Performance deteriorates due to cell imbalance.

To guarantee that all cells retain comparable voltage levels, the balancing circuit redistributes charge, increasing longevity and efficiency.

4. Protection Circuit

By turning off current when thresholds are crossed, this protects the battery pack from issues including short circuits, thermal runaway, and voltage spikes.

5. Communication Interface

This component allows the battery management system to connect with other systems (e.g., car control units, power grids, or cloud platforms) utilizing protocols like CAN, SMBus, or Modbus.

How Does a Battery Management System Work?

The operation of a battery management system can be separated into various intelligent processes:

Measurement: Temperature, current flow, and voltage readings for each cell in real time.

Analysis: SOC and SOH estimation using algorithms like Coulomb counting and Kalman filtering.

Balancing: Either actively or passively balancing the charge levels in each cell.

Protection: Isolating the battery pack when dangerous situations emerge.

Reporting: Data transmission for analytics and control to cloud servers, IoT systems, or onboard displays.

Throughout the charging and discharging process, the battery management system runs constantly, according to load demands and external circumstances.

Applications of Battery Management Systems

Battery management system technology applications are still expanding:

1. Electric Vehicles (EVs)

For fault isolation, range prediction, thermal control, and fast-charging safety, EVs mostly rely on BMS.

2. Grid-Scale Storage

Strong BMS units are necessary for battery farms that supply electricity to renewable grids in order to coordinate with energy management systems (EMS), manage thousands of cells, and guarantee reliable performance.

3. Portable Electronics and Power Tools

For tiny devices, a reliable battery management system ensures safe charging and optimal runtime without overheating.

4. Drones and Robotics

Flight stability, motor control, and battery safety during intense maneuvers all depend on a responsive BMS.

Modern Trends in Battery Management System Technology.

As demand increases, the battery management system’s capabilities keep developing:

Integration with AI: Adaptive algorithms to improve anomaly detection and state predictions.

IoT Connectivity: Streaming data in real time to cloud platforms for remote diagnostics and fleet monitoring.

Modular Design: Scalable designs for everything from 35S EV battery packs to 3S portable instruments

Cybersecurity: Protecting the BMS against hacking is increasingly more important as connectivity increases.

Maintenance and Best Practices

To maintain optimal battery management system performance:

Perform periodic software updates

Calibrate sensors regularly

Inspect connector integrity

Analyze logs for trends in degradation

Avoid extreme temperature and humidity exposure

By taking these actions, battery and BMS lifespans can be greatly increased.

Impact of U.S. Tariffs on the BMS Industry

A 25% tariff on imported cars and auto parts, including parts for battery management systems (BMS), was one of the major tariffs the US imposed in April 2025, impacting a number of businesses.

Costs, supply chains, and market dynamics have all been significantly impacted by these policies in the BMS sector.

1. Increased Costs for BMS Components

Importing vital BMS parts like microcontrollers, electronic control units, and lithium-ion batteries has become more expensive as a direct result of the recently implemented tariffs.

For BMS manufacturers, this rise in component costs has resulted in increased overall production costs, which could raise final consumer pricing.

For example, Tesla uses imported parts, with over 35% of its components coming from elsewhere, even though it manufactures its cars domestically.

Tesla’s production costs could rise by almost $4,000 per vehicle as a result of the tariffs, which could result in a 9% increase in customer prices.

2. Supply Chain Disruptions

A worldwide supply chain is essential to many BMS manufacturers, especially when it comes to sourcing parts from nations like China.

These long-standing supply chains have been upset by tariffs, forcing businesses to look for new suppliers or think about moving their manufacturing sites.

These kinds of changes are frequently expensive and time-consuming, which could cause production delays and raise operating costs.

Furthermore, some businesses are considering reshoring their operations to the United States as a result of the tariffs, but with difficulties because of increased domestic manufacturing costs and the demand for trained labor.

3. Impact on the Electric Vehicle (EV) Market

Electric vehicle performance and safety depend heavily on battery management systems.

The overall cost of producing EVs is impacted by the higher prices of BMS components brought on by tariffs.

Manufacturers may have to decide whether to pass these extra expenses on to customers, which could result in higher retail prices, or absorb them, which would lower profit margins.

This situation can reduce customer demand and limit the rate at which EVs are being adopted in the US market.

4. Strategic Industry Responses

Business associations and industry executives have voiced concerns about the possible economic effects of the tariffs.

Business executives have cautioned that the tariffs may cause inflation and economic instability in addition to raising prices for American consumers.

To lessen the impact, some businesses are looking into tactics like requesting tariff exemptions, expanding their pool of suppliers, or making investments in domestic manufacturing capacity.

5. Potential for Retaliatory Measures

Concerns regarding possible retaliatory actions from impacted trading partners have also been raised by the implementation of these tariffs.

Countries affected by the U.S. tariffs may impose their own tariffs on American goods, which could further disrupt international trade relations and supply chains, increase trade tensions, and create an uncertain environment for businesses operating in the BMS sector.

Impact of U.S. Tariffs on the BMS Supply Chain

The BMS supply chain has been greatly disrupted by the U.S. administration’s imposition of tariffs on imported goods, including a 25% duty on vehicle parts including lithium-ion batteries and related components.

Manufacturers who depend on imported BMS components now face higher prices as a result of these levies, which has caused supply chain strategies to be reevaluated.

Strategic Responses from Industry Players

Businesses are implementing a number of tactics in reaction to these tariffs:

Diversification of Supply Chains: Manufacturers are exploring alternate suppliers in countries not affected by the tariffs to reduce cost hikes.

Investment in Domestic Production: Some corporations are investing in local manufacturing facilities to lessen dependency on imported components and avoid tariff-related costs.

Collaborations and Partnerships: Establishing strategic partnerships with other industry participants in order to pool resources and technology and lower production costs overall.

Ayaa Tech: A Pioneer in BMS Innovation

Ayaa Tech. has led the world in developing customized battery management systems for more than 18 years.

Ayaa Technology serves customers in the United States, Canada, Germany, Japan, and Australia and offers complete BMS solutions for:

EVs and e-mobility

Energy storage systems

Drones and robotics

Medical equipment

Consumer electronics

What sets Ayaa apart?

R&D Excellence: Multi-protocol communications, active/passive balancing, and sophisticated SOC/SOH estimate methods.

Modular Design: More than 400 BMS types with passive or active balancing options, ranging from 1S to 35S and 1A to 320A.

Global Engineering Support: Specialists in European and American battery certification requirements.

Manufacturing Precision: Complete supply chain management and strict quality control procedures.

Working with Ayaa Technology guarantees that your battery management system is future-ready, tariff-resilient, and customized for your application, regardless of whether you’re an OEM, energy business, or battery integrator.

The battery management system is now an intelligent gateway to battery longevity, safety, and efficiency rather than merely a passive controller.

A well-designed BMS is essential to remaining competitive as global supply chains change and energy demands increase.

It is the unsung hero of every high-performing battery system, because to its scalable architecture, clever software, and sturdy components.

Ayaa Technology is still a vital strategic supplier that may assist businesses in maintaining cost-effectiveness and innovation, even in the current trade environment.

Despite the uncertainty brought on by the new tariffs, U.S. clients can rely on Ayaa’s experience designing battery management systems for Li-ion, LiFePO4, and LTO chemistries, which guarantees both quality and compliance.

Long-Term Industry Shifts

Reshoring Trends

To get around erratic import taxes, American companies can look into nearshoring or reshoring BMS production.

Innovation in Cost-Reduction

To preserve performance while controlling rising costs, manufacturers are probably going to make investments in streamlined designs, standardized components, and intelligent diagnostics.

Supplier Diversification

Companies may actively seek non-Chinese BMS suppliers or require dual-source strategies to build tariff resilience.

Global Implications

Because of the 20% surcharge, German BMS manufacturers—who are renowned for their precision-engineered products—also have less ability to compete in the U.S. market.

Japanese suppliers are expected to gain from the April 2nd tariffs as alternate partners in premium markets, albeit being less immediately impacted.

The battery management system business has faced significant challenges as a result of the 2025 U.S. tariffs, but they have also offered opportunities for innovation, localization, and strategic partnerships.

Businesses like Ayaa Technology Co., Ltd. are essential in helping customers navigate this shift by providing affordable, specially designed, and legally compliant BMS solutions that guarantee EV and energy storage projects remain on schedule.

Agile supply chains and international technological collaborations will determine who drives the development of the next generation of intelligent, sustainable energy systems as the sector continues to change in a protectionist global trade climate.

Shenzhen Ayaa Technology Co., Ltd. is a prime example of what it means to be at the forefront of technological innovation.

Ayaa is the partner to choose if you’re looking for a dependable, high-performing battery management solution that meets your needs.

Contact Us

SHARE

News Recommend

-

How does AYAATECH BMS work in E-scooters

01/16/2025 -

2024 battery show in Detroit,USA.

10/08/2024